Our Story

Packit Packaging was established in 2000 by two innovative Dunedin Toolmakers to fill a niche in the market to supply injection moulded food packaging to small and medium-sized businesses. Now 22 years later, Packit offers a wide range of products and designs to a number of diverse companies.

Packit now employs 16 staff and continues to be locally owned and operated. We have an innovative in-house design team, up to date manufacturing processes and the latest manufacturing software.

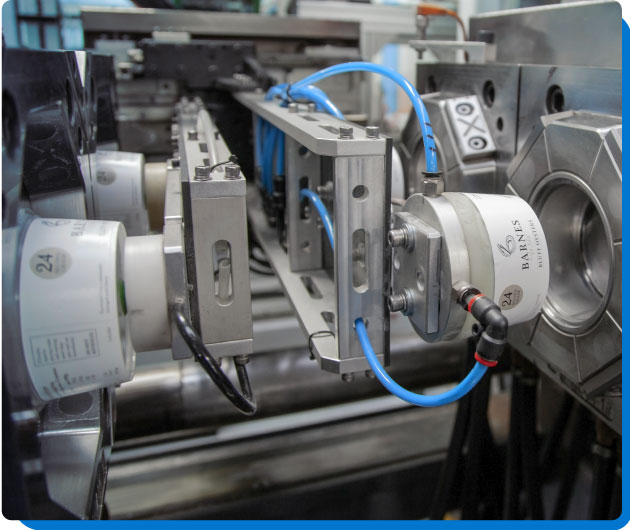

Injection Moulding Technology

Injection Moulding Technology (IMT) is the process of injecting heated plastic into a mould, using extreme pressure, and then cooling and solidifying the plastic to obtain the desired shape. This method of moulding is highly efficient and cost-effective for our customers. IMT allows for the products to be consistent, which is crucial when manufacturing high volumes. It is a guarantee that each container will be the same as the last batch and the next. Injection Moulding Technology allows us to create a high-quality product every time for our customers.

Packit Team

Jan Swann

Sales Manager

I have been in the plastic packaging industry for 23 years. I started in Customer Services and then moved to Account Management & Sales. My experience means I can understand customers' requirements and offer them solutions promptly. I ensure a smooth process from order to delivery whether this is a plain or decorated product. I am passionate about my role in this industry and love meeting new clients and being part of their growth journey.

Jamie Hodgins

General Manager

I have over 25 years of experience in plastic food packaging design and tooling. I have a background in mechanical engineering and have spent most of my time in management positions while still working on the shop floor to better understand the day to day processes. I enjoy working with customers to bring their projects to life.

Together everyone achieves more

Gareth Wong-Smith

Storeman

I am a storeman that has worked in the food industry most of my working life, with a background in the food safety industry I strive to work to a very high standard of cleanliness and safety. I have taught myself the skills that I have obtained over the years and have applied those skills to my role here at Packit.

Environment and Sustainability

We introduced a scheme to collect and recycle your Number 5 PP plastic containers. This gives those containers a second chance to be remade into new items and not go into landfills. Our goal is to reduce waste and improve our impact on our natural environment. Better choices at home, recycling our everyday plastic items, we can help to minimise waste going into our landfills which helps to decrease pollution on our land and in our waters.

100% of Packit’s internal plastic waste is recycled right here in New Zealand and goes on to make other local industrial and building products. Recycle It is a PackIt initiative to ensure 100% of Number 5 PP collected is recycled and reused.