Innovation

At Packit we are always looking for innovative new ways of processing more efficiently, making our packaging more sustainable and listening to our customers to fill their needs. We regularly attend international trade and technology shows as well as visit other moulding facilities which gives us the ability to bring the best of the industry to you. Thin-walled packaging is a fine art so when choosing your next packaging partner make sure you pick the best.

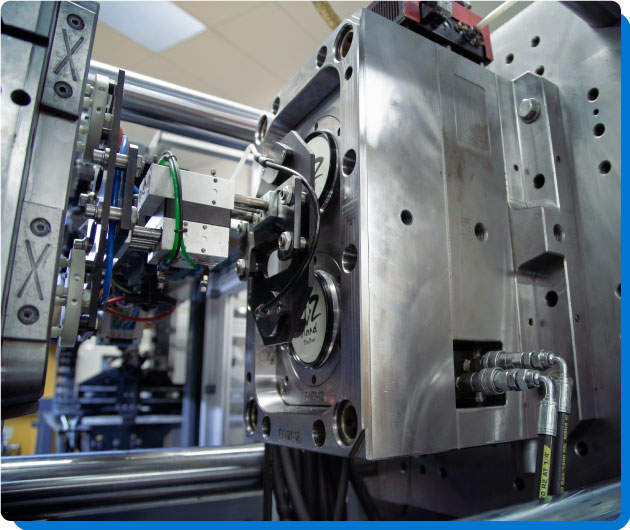

IML Advantages

In-Mould Labels (IML) have many advantages. IML has outstanding print quality including photographic images. IML offset printing technique ensures high-resolution images, with up to 6 colours, for your labels.

IMLs are durable, humidity resistant and temperature stable, which makes them an excellent choice for frozen and refrigerated products. Scratches, cracks, and wrinkles can harbour bacteria. IMLs are also scratch-resistant, it cannot crack or shrink and is not susceptible to wrinkles, making them more hygienic.

IML Products have a shorter production time and therefore have lower production costs, which makes our pricing highly competitive. They are also produced in a single step which means no need to transport or store blank products.

One of our biggest missions and goals here at Packit is to be as environmentally friendly as we can, Packit recycles 100% of its plastic waste and rejected products, and we also help our customers to recycle where they can. IML products are a mono-product where both the plastic part and label are made from the same material and therefore can be fully recycled.

Packit vs alternatives

Packit is locally owned and operated right here in Dunedin. We know what New Zealand products represent and how they reflect our country. We have those same beliefs, and as a plastic packaging company, we want to implement our values into our products.

We are a customer-focused company and we listen to what our customers want and help you to bring your packaging idea to life. We have one of the best sales teams in the business and they know how to best support our customers.

Most alternative packaging suppliers are overseas owned and are not aware of the pride associated with New Zealand products. We have seen a rise in corporations and the relationship they have with their customers is disconnected, and they are just another order.

Improved appearance and increased production efficiency

Production flow

We are with you from beginning to end; here’s how.

You place your order with us, our sales team will then confirm your order and enter it into our inventory software. Our store manager then confirms the raw materials required and allocates the carton labels and production information.

From there, our operations manager schedules the job in our production planning software, so that our manufacturing team can manufacture the product to meet your deadline. We then complete your order and conduct quality assurance to ensure your product is at the highest standard possible.

The finished cartons of your product are then taken through to the store to be palletised and wrapped so that we can dispatch your product out to you and you fill it for the shelf.

Environment and Sustainability

We introduced a scheme to collect and recycle your Number 5 PP plastic containers. This gives those containers a second chance to be remade into new items and not go into landfills. Our goal is to reduce waste and improve our impact on our natural environment. Better choices at home, recycling our everyday plastic items, we can help to minimise waste going into our landfills which helps to decrease pollution on our land and in our waters.

100% of Packit’s internal plastic waste is recycled right here in New Zealand and goes on to make other local industrial and building products. Recycle It is a PackIt initiative to ensure 100% of Number 5 PP collected is recycled and reused.

Frequently asked questions

We are here to help! Check out some of our frequently asked questions below…

Are your products made using FDA approved materials?

Yes all our products are manufactured using FDA approved materials

What is Packit’s minimum run quantity?

The minimum run quantity is 10,000 parts, we can in some instances do smaller runs but you will have to pay a small fee to change over tools

Does Packit operate a food safety program?

Packit maintains a HACCP food safety system that is annually third party verified

Are your products recyclable?

Yes 90% of Packit’s products are manufactured from #5 PP plastic that is fully recyclable, the other 10% is made from #4 LDPE these are also recyclable but only collected through limited curbside recycling, Packit also recycles 100% of its own plastic waste.

Can I have a custom-designed Product and mould?

Yes, Packit can work with you to design a product and mould it to suit your requirements, we can also offer 3D printed models to validate the product design.

Can you make your packaging out of 100% recycled material?

At this stage, only non-food grade products can be made from recycled PP, but in the near future we will be offering recycled food grade PP materials when they become available

What colour packaging do you offer?

We have an extensive list of colours available for offer. We want to make your product come to life and don’t want you to be restricted in your choices. Talk to our sales team about your requirements.